Complete set soybean oil making machine introduction:

Cooking oil manufacturing machine is used to process seeds to high quality cooking oil. But about extracting crude oil , we have two methods to process seeds to oil, one is mechanical press method , the other is solvent extraction method.

Cooking oil manufacturing machine with prepress line.

Cooking oil manufacturing machine with solvent extraction line.

Cooking oil manufacturing machine with refinery line.

About the details , welcome to contact us.

Basic information about complete set soybean oil making machine:

1.Pretreatment and prepress step of soybean oil making machine.

Brief processes:

Raw material--Magnitic seperating--Metal impurities--Cleaning--Other impurities--Husking--Sunflower seed hull--Cooking--Prepressing--Crude oil--Sunflower seed cake--Extracting Workshop

|

| soybean oil pretreatment and pressing process |

Functions of main parts:

Magnitic seperating:In order to remove the metal impurities, so that can prevent damaging the equipment and occuring safety accidents.

Cleaning: To remove the imourities in the raw matrial such as soil, stem and leaf, hull and moldy seeds.

Husking: In order to improve the oil yielding rate and the quality of crude oil and meal, reduce the wear to the equipment, the hull must be removed.

Cooking: This processing can improve prepressing oil yielding rate and the quality of the cake, adjust the moisture, temperature and plasticity of the flake.

Prepressing:To squeeze out part of the oil in the raw material, and improve extracting effect.

Related post: Soybean oil pretreatment & prepressing machine

Pictures of prepress machines:

2.Solvent Extracting step of soybean oil making machine:

Brief processes:

Fresh Solvent--Cake--Extracting--Wet Meal--Desolventising--Meal--Miscella--Evaporating and stripping--Solvent mixture--Condensing and Recovering--Crude Oil--Solvent Recycling--Refining Workshop.

|

| soybean oil solvent extraction process |

Functions of main parts:

Extracting:To extract the oil in the cake by solvent, the general solvent is 6# extraction solvent oil or commercial hexane.

Desolventising:To remove and recover the solvent in the meal; Dry and cool down the meal at the same time.

Evaporating and stripping:Heating the the miscella by indirect steam, so that can vaporize the solvent and concentrate the miscella.

Solvent recycling: This process is to recover the solvent, decrease solvent comsuption, keep safety prodution and improve product quality.

Related post: Soybean oil solvent extraction plant

Picture of solvent extraction machines:

3.oil refining step of sunflower oil making machine.

Brief processes:

Crude Oil--Hot water--Degumming--Oil Foot--Alkali liquor--Deacidfying--Soap Stock--

Activeted Clay--Decoloring --Waste Clay--Deodorizing--Dewaxing--Wax--Refined Oil

|

| Soybean oil refining process flowchart |

Functions of main parts:

Degumming:To remove the colloid soluble impurities, and prepare for the subsequent refining process.

Deacidfying:To remove the free fatty acid in the crude oil.

Decoloring: To remove the pigment in the crude oil by adding active clay, so that can improve the oil quality.

Deodorizing:To remove the odor in the oil, so that can improve the flavor, stability, color and quality of the oil.

Dewaxing: To renmove the wax in the oil and improve the quality of the oil.

Related post: Soybean oil refinery plant

Pictures of sunflower oil refining machine:

|

| soybean oil refining machine |

Refined sunflower oil quality:

| Sunflower Oil Quality Index (The index of soybean oil, rapeseeds oil, oiltea seed oil are similarly) | ||||

| Item | Quality index | |||

| Crude oil | 1st grade | 2nd grade | ||

| Colour and lustre(25.4mm) | _ | Y15 R1.5 | Y25 R4.0 | |

| Flavor and taste | Crude sunflower oil smell, no peculiar flavour | The original sunflower flavor, no peculiar flavour | The original sunflower flavor, no peculiar flavour | |

| Transparency | _ | Clear and transparent | Clear and transparent | |

Moisture & Volatile matter

/ % ≤

| 0.2 | 0.1 | 0.15 | |

Impurities/% ≤

| 0.2 | 0.05 | 0.05 | |

Acid value

(KOH)/(mg/g)≤

| 4 | 1 | 2.5 | |

Peroxide value/

(mmol/kg) ≤

| 7.5 | 6 | 7.5 | |

Solvent residue

/(mg/kg) ≤

| 100 | Not be detected | Not be detected | |

| Test tempeature (280 °C) | _ | No educt, Lovibond Tintometer:Yellow value not changed,red value increasing<0.4 | Trace of educt, Lovibond Tintometer: Yellow value not changed,red value increasing<0.4 blue value<0.5 | |

Contact information:

http://www.edibleoilextractionmachine.com

whatsapp/wechat: +86 13526627860

Email:oilmachine@doinggroup.com

Get the price

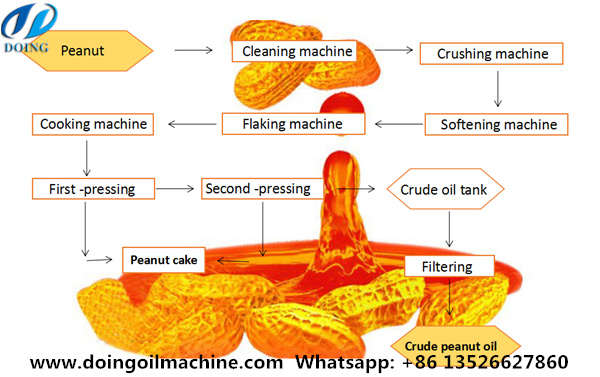

Small scale peanut oil making machine

Small scale peanut oil making machine Peanut oil making process flow chart

Peanut oil making process flow chart

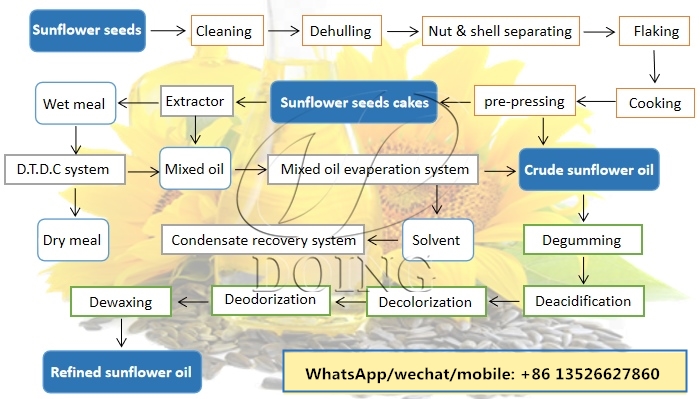

1-10tpd sunflower oil sunflower oil making machine

1-10tpd sunflower oil sunflower oil making machine