soybeanoil processing plant soybean oil processing plant soybean oil extraction machine pri

Product Description

|

| 1-1000tpd soybean oil processing machine |

soybean oil processing plant is used to derive oil from soybeans, including pressing and solvent extraction. We are the manufacturer of soybean oil processing plant. Here we will introduce the main parts of the soybean oil processing plant (solvent extraction).

As manufacturer of soybean oil processing plant, we can offer whole line or part of soybean oil processing plant with general capacity from 10TPD to 6000TPD. For special capacity, our engineer can also help design and install workshop according to your capacity and requirements.

As manufacturer of soybean oil processing plant, we can offer whole line or part of soybean oil processing plant with general capacity from 10TPD to 6000TPD. For special capacity, our engineer can also help design and install workshop according to your capacity and requirements.

1.Pretreatment part of the soybean oil processing plant:

Soybean → Cleaning → Crushing → Softening → Flaking → Puffing (Drying) → Solvent extraction

Soybean → Cleaning → Crushing → Softening → Flaking → Puffing (Drying) → Solvent extraction

a. Cleaning :

Cleaning section removes impurities in soybeans through magnetic drum, cleaning seive, stoning machine, etc. Soybeans from different regions need different cleaning machines to remove impurities. And our engineer can help you choose most suitable sets of cleaning machines according to your material.

Cleaning section removes impurities in soybeans through magnetic drum, cleaning seive, stoning machine, etc. Soybeans from different regions need different cleaning machines to remove impurities. And our engineer can help you choose most suitable sets of cleaning machines according to your material.

b. Crusher:

It is used for crushing soybean into small pieces, which can help to extract more oil from the seeds.

It is used for crushing soybean into small pieces, which can help to extract more oil from the seeds.

c.Flaking Machine/Flake roll:

This machine can be made the soybean to 3mm-5mm flakes , it will destroy the soybean oil cell which is easy extraction oil out.

This machine can be made the soybean to 3mm-5mm flakes , it will destroy the soybean oil cell which is easy extraction oil out.

d:Pre-pressing

this machine used for press soybean into soybean oil

[You may interested in : Soybean oil pretreatment & prepressing machine ]

2.Solvent extraction of the soybean oil processing plant:

Soybean flakes → Extractor → Desolventizer Toaster → Stripping Tower (Oil Stripper) → Crude Soybean Oil

|

| Soybean oil solvent extraction process flowchart |

The pretreated soybean flakes are sent to soybean solvent extraction plant. The plant uses a kind of solvent(normal hexane) to absorb the oil from soybean, and then the machines separate the solvent from crude soybean oil, solvent is used for recycling and crude soybean oil is refined by refinery plant.

|

| Soybean oil solvent extraction plant |

3. Refinery plant of soybean oil processing plant:

Water→ Degummin→ Gums

Alkali→ Deacidification→ FFA

White Clay→ Decolorization→ Pigments

Steam→ Deodorization→ Beany Flavor

|

| Soybean oil refinery process flowchart |

a.Degumming and deacidification section:This part is used for removing the phospholipid and FFA in the crude oil.

b.Decolorization section: this part is utilizing the white clay to get rid of the pigment in the soybean oil. It can make the soybean oil much more clearer.

c.Deodoriztion section: This part is using the direct steam to take the beany flavor away, to make the soybean oil good flavor.

|

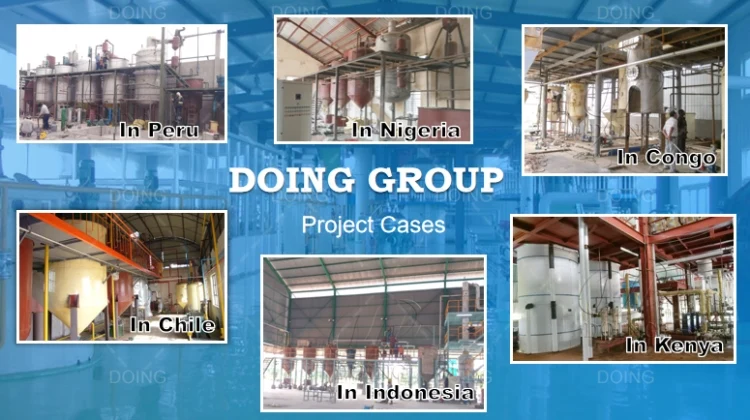

Edible oil refinery plant projects that we have installed

We have been concentrated in soybean oil processing plant for decades, and our professional engineer can help you design most suitable soybean oil processing plant according to your requirements and conditions. If you are interested in soybean oil processing plant, please feel free to contact us.

Contact infromation:

whatsapp/wechat/mobile : +86 13526627860

Email: oilmachine@doinggroup.com

没有评论:

发表评论