Sunflower oil is an essential ingredient in our daily lives. and the production of sunflower oil requires different types of sunflower oil making machines. Among them, the automatic temperature-controlled vacuum filter integrated oil press machine, also known as the sunflower oil making machine with filter, is one of the most popular machines on the market.

The price of sunflower oil making machine with a filter

The price of sunflower oil making machine with a filter ranges from 4000-10000. Multiple model options are available to suit different customer needs and budgets. The power and processing capacity of each model varies, resulting in different prices. Therefore, you can select the most suitable model based on your needs and budget. If you want to learn more detailed information about the oil press machine with a filter cartridge for sunflower oil, you can contact Henan Glory Company. Our professional sales staff will serve you and help you select the most suitable equipment according to your needs.

The sunflower oil making machine with a filter is designed to make the production of sunflower oil more efficient and convenient. It has a processing capacity of 1-10tpd and is mainly suitable for small and medium-sized sunflower oil processing plants. The sunflower oil making machine with a filter is equipped with a powerful motor to ensure efficient and effective oil pressing. It consists of three main parts: the temperature control system, the oil pressing part, and the filtering part.

The temperature control system

The temperature control system is an important component of the sunflower oil making machine with a filter. It uses an electric heating ring device to heat the press, which has an automatic temperature control function, replacing the traditional friction heating method of the press. This shortens the preheating time, makes the press function quickly and normally, reduces energy consumption and machine wear. The temperature control system ensures that the sunflower oil making machine with a filter is heated to the specified temperature before the oil is transferred from the hopper to the pressing chamber. At the same time, the temperature control system of the sunflower oil making machine with a filter is easy to operate, with a user-friendly interface that allows operators to easily control temperature and other settings. The sunflower oil making machine with a filter is also equipped with safety features to ensure the operator’s safety when using the machine.

The oil pressing part

The oil pressing part is the heart of the sunflower oil making machine with a filter. Under the action of the pressing screw, the oil is continuously pushed inward. Our pressing screw adopts 20 carbon steel to ensure efficient and effective oil extraction. Moreover, our pressing screws are polished before leaving the factory to ensure smoothness and prevent blockage caused by rough pressing screws, to a certain extent, ensuring the smoothness and efficiency of machine operation. The oil pressing part is designed to process various oilseeds, including soybeans, peanuts, sunflower seeds, rapeseed, cottonseed, etc.

The filtering part

The filtering part of the sunflower oil making machine with a filter is responsible for filtering the pressed sunflower oil. The oil is filtered through the filter to remove residues and obtain pure sunflower oil. The oil also does not contain impurities, and its shelf life is longer. The filtering part is also equipped with a vacuum pump, which helps to filter the crude oil more effectively.

🌟Contact information:

🔍My Whatsapp/Wechat: +86 13526627860

🌍Website1: http://www.sunfloweroilextractionmachine.com

🌍Website2: http://www.cookingoilmillmachine.com

📩Email: market@doinggroup.com

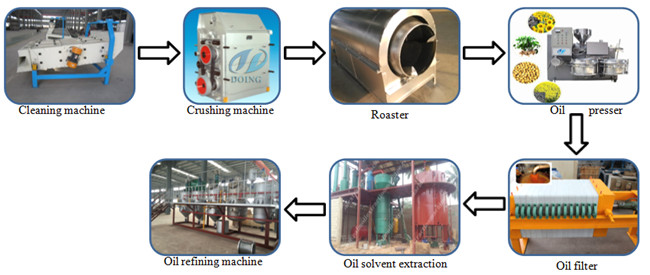

Sunflower oil extraction process is the same with peanut oil extraction process as the GIF image shows

Sunflower oil extraction process is the same with peanut oil extraction process as the GIF image shows Sunflower oil extraxction process machinery

Sunflower oil extraxction process machinery Sunflower oil presser machine

Sunflower oil presser machine Our sunflower oil extraction machine can process the oil seeds as the photos show

Our sunflower oil extraction machine can process the oil seeds as the photos show