Generally, a complete set of groundnut oil processing plant for producing edible oil includes 3 production processes: oilseeds pre-treatment and pre-pressing machine, cooking oil solvent extraction plant and cooking oil refining machine. The main processing machinery includes oilseeds cleaning equipment, dehulling machine, oilseeds cooker or roaster, peanut oil press, filter press, oil refinery machine and oil filling or bottling device.

|

| Groundnut oil processing machine |

For the ones who want to run a small scale groundnut oil processing plant for manufacturing edible oil, traditional pure physical pressing method should be the first choice! Four procedures are generally included, shelling, roasting, oil expelling and filtering. After these processes, we can get crude groundnut oil which can be ate directly.

Groundnut oil processing process is as follows:

Groundnut Seeds → Cleaning machine →Shelling → Cooking / Roasting → Oil Pressing → Oil Filtering → Crude groundnut oil

Main Groundnut Oil Processing Steps:

1)-Seeds Cleaning Process

Remove impurity (silt, pebble, iron chip, etc.) to reduce wear and tear on internal parts of oil press and improve oil yield. The main equipments includes cleaning screen, stoning machine, magnetic separation machine.

2)-Peanut Shelling Process

Put the harvested peanut into professional groundnut shelling machine to remove the shells and get the seeds (kernel content: 65%-75%). With the development of vegetable oil production industry, shelling process been basically mechanized. The production efficiency is also greatly improved!

3)-Seeds Roasting Process

The groundnut kernels are then put into the roasting machine with automatic temperature control system. It is the key step to determine the yield of peanut oil. Experienced operators can control the cooking temperature and time very well to get high oil yield.

|

| Groundnut cooker machine |

4)-Oil Expelling / Pressing Process

A good unit of groundnut oil press machine can not only save a lot of trouble in cooking oil processing business, but also can reduce production cost and increase profit. Actually, screw type peanut oil press machine can process various different oilseeds, such as rapeseed, soybean, cottonseed, tea seed and other vegetable seeds.

|

| Groundnut oil press machine |

5)-Oil Filtration Process

The oil expelled from oil presses might looks a little muddy, and doped with some foam. So filter press is needed to ensure the purity of groundnut oil with gold color and good flavor.

|

| Groundnut oil filter machine |

If you are planning to buy groundnut oil processing machine to start cooking oil processing business, Henan Glory Company maybe a goopd choice. Welcome to visit our factory for on-site inspection, or send us an inquiry online to enjoy one-one service on customized groundnut oil manufacturing business plan, equipment selection guide and cost details! Looking forward to your consultation.

Contact information

http://www.edibleilextractionmachine.com

whatsapp/wechat/phone: +86 13526627860

Email: oilmachine@doinggroup.com

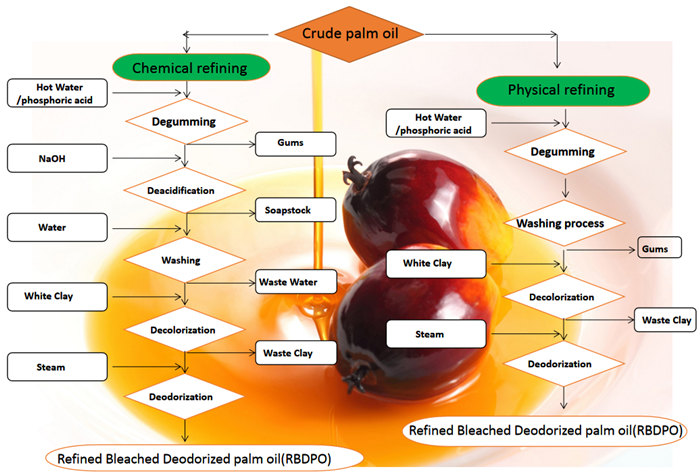

Physical refining and chemical refining process of edible oil

Physical refining and chemical refining process of edible oil 100tpd palm oil physical refining project case in Kenya

100tpd palm oil physical refining project case in Kenya 20tpd palm oil chemical refining project case in Peru

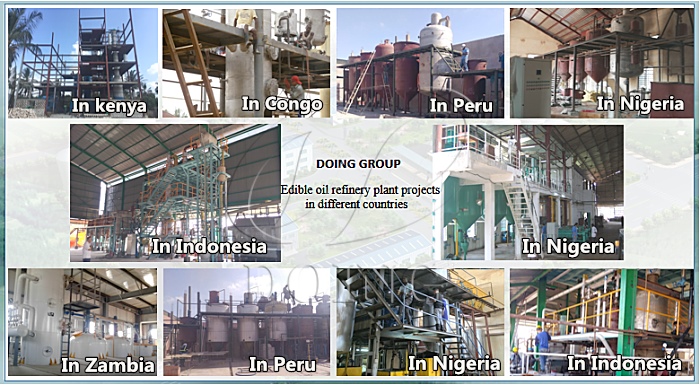

20tpd palm oil chemical refining project case in Peru Edible oil refinery plant projects were built by Henan Doing Machinery

Edible oil refinery plant projects were built by Henan Doing Machinery

Single screw soybean oil press machine

Single screw soybean oil press machine