Sunflower oil is one of the five most promising oils in the world. It is good for health. Nowadays, not only the largest sunflower seed producer country Argentina but nearly all rest countries in the world are starting sunflower oil processing business. But how to make the sunflower oil? What are the steps of making sunflower oil? Here, we summarized the production steps of making sunflower oil in sunflower oil mill, I am sure that will be helpful.

|

| Sunflower seeds and sunflower oil |

At present, there are two main production processes in sunflower oil production, namely mechanical pressing and solvent extraction. They all widely used in sunflower oil production process, as for which technology to choose is decided by your sunflower seed capacity, output market, factory requirement, local policy and so on.

The main steps for mechanical pressing technology is:

Cleaning-husking-cracking-flaking-cooking-pre-pressing-pressing |

| Sunflower oil making machine |

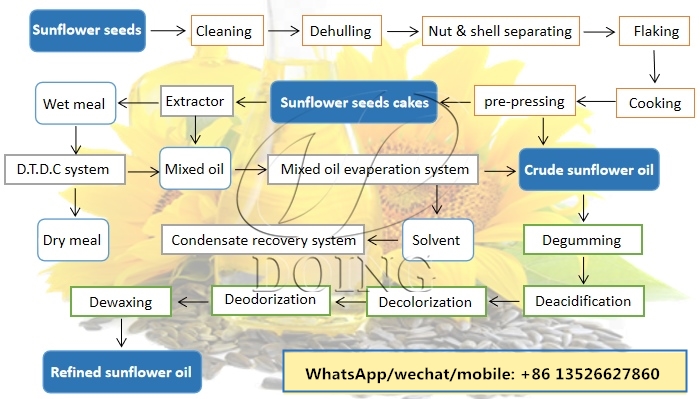

The main steps for solvent extraction technology is:

Cleaning-husking-cracking-flaking-cooking-pre-pressing-solvent extraction |

| Sunflower oil making process flowchart |

Both Mechanical press way and solvent extraction way have their own advantages which suitable for different sunflower oil production situation. Mechanical press way oil residue (5-7%) will be more than solvent extraction way(lower than 1%), but aiming to small capacity lower than 50tpd, its investment cost will be lower. If your production capacity larger than 100tpd, solvent extraction technology investment cost will be lower than mechanical press way.

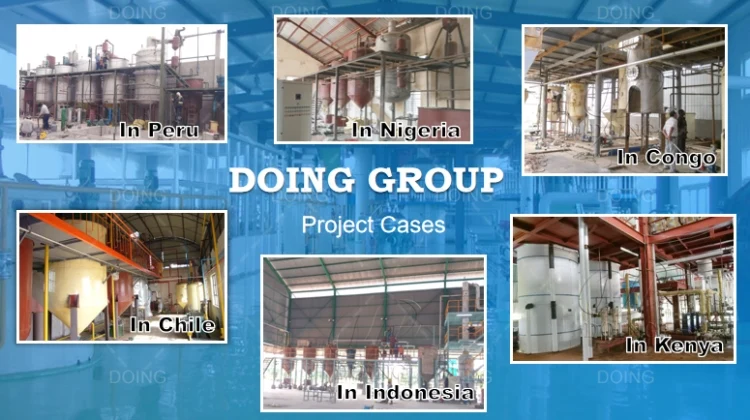

If you want to process sunflower seeds within 1-10tpd, starting with the whole sunflower oil processing line will be not economical. We Henan Doing Mechanical Equipment Co.,ltd engineer suggest you to buy one set integrated sunflower oil press machine with filter and a roller cooker. That will be profitable for a starter.

1-10tpd sunflower oil sunflower oil making machine

1-10tpd sunflower oil sunflower oil making machineIf you have special requirements for sunflower oil mill plant project, please leave your contacts, we will design tailored-made plan for you to reach your sunflower oil and cake standard.

Contact information:

http://www.edibleoilextractionmachine.com

whatsapp/wechat/mobile: +86 13526627860

Email: oilmachine@doinggroup.com